REXPEARL™ EMA

REXPEARLTM EMA is a random copolymer of ethylene and methyl acrylate with low melting point and flexibility.

Its thermal stability is superior compared to EVA, and no acid or toxic gases are generated even if it decomposes.

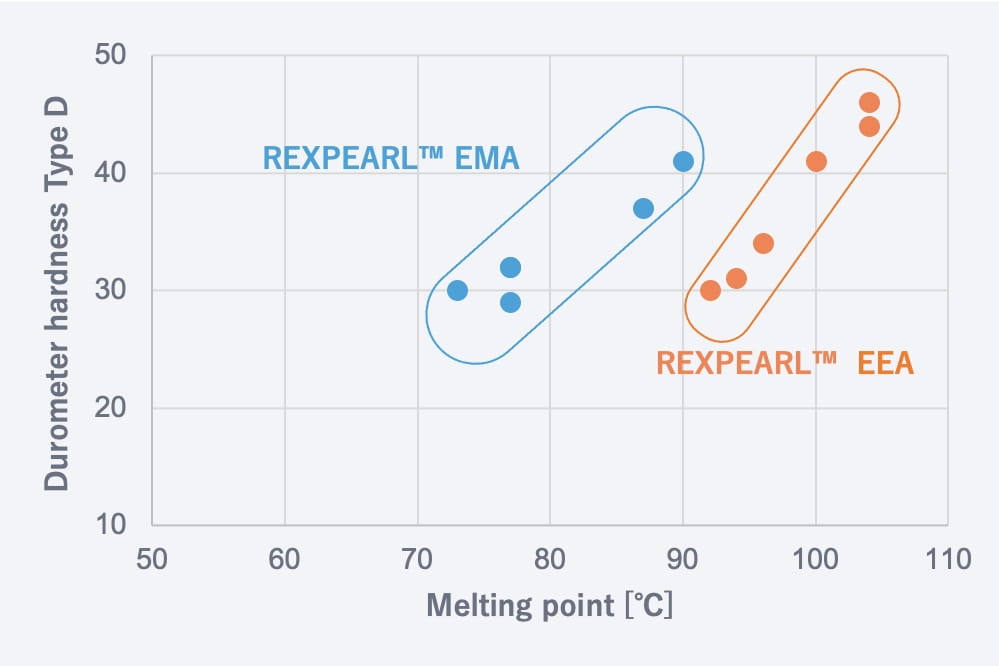

Flexibility

- Copolymerization of ethylene and methyl acrylate enhances flexibility.

- Its melting point is lower and flexibility is superior compared to REXPEARL™ EEA.

- Due to its low melting point, it can be processed not only by extruders but also by calendar molding.

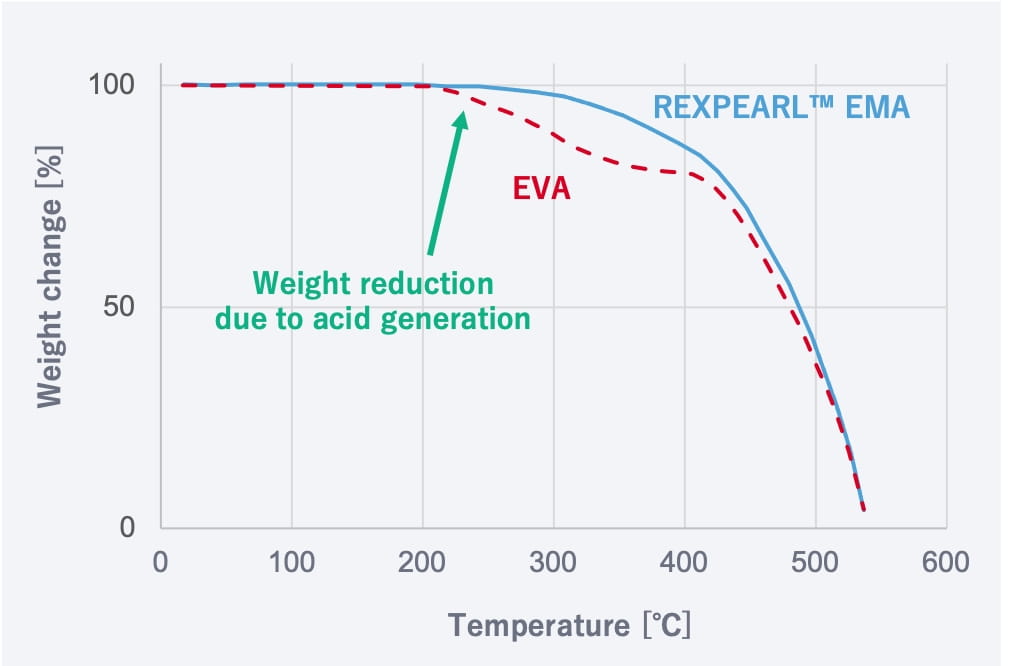

Thermal decomposition resistance

- As REXPEARL™ EEA has superior thermal stability compared to EVA, there will be no acid formation even if it decomposes.

- As it exhibits the same thermal decomposition behavior as polyethylene, it can be molded and processed in general molding machines.

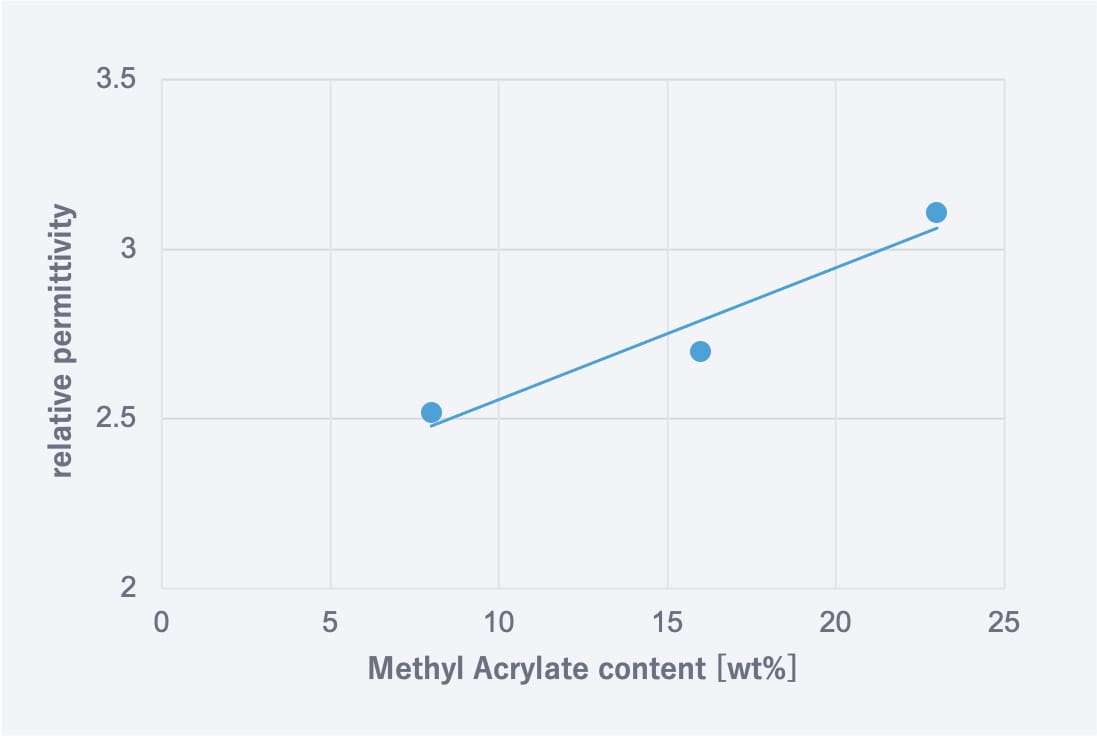

High-frequency sealing

- With the presence of acrylate in the molecular structure, relative permittivity is higher than that of common polyolefin.

- Acrylate content correlates with relative permittivity, and the higher the content, the higher the relative permittivity becomes.

- You can use high-frequency welding, which is generally difficult for polyethylene, by using REXPEARL™ EEA.

Low melting point

- With the presence of acrylate in the molecular structure, REXPEARL™ EEAs’ crystallinity is low and its melting point is particularly low compared to other thermoplastic resins.

- We have grades which can be processed at temperatures of 100°C or lower.

- REXPEARL™ EEA has excellent heat sealability and does not show hot tacks even at low temperatures.

- It can be used for applications that require low-temperature molding, such as when molding polyethylene with fillers that may deteriorate or discolor by heat.

Silk-Like Smoothness

- We have a grade which makes unique films with silk-like smoothness.